Innovation Lab HySPRINT

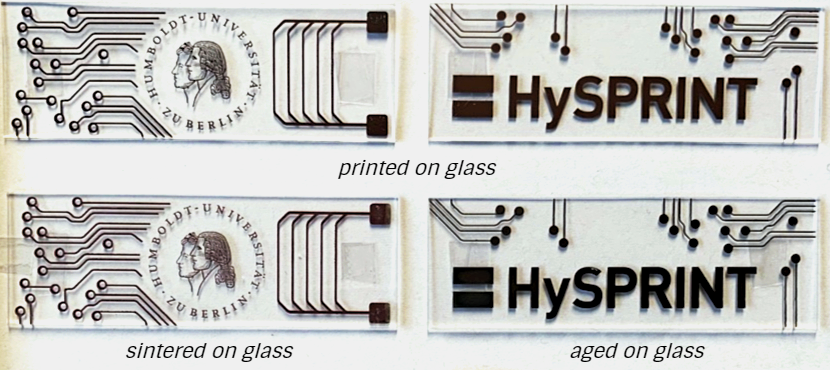

Generative manufacturing processes for hybrid components (Joint lab with HU Berlin)

Since August 2018, the HZB group of Dr. Eva Unger (Hybrid Materials Formation and Scaling), who are based in the HySPRINT perovskite lab, and the group of Prof. Dr. Emil List-Kratochvil (Hybrid Devices) from the Integrative Research Institute for the Sciences (IRIS) of Humboldt-Universität zu Berlin (HU Berlin), have cooperated on the long-term project “Generative manufacturing processes for hybrid components” (GenFab).

List-Kratochvil and Unger develop large scale (opto)electronic devices, printed solar cells and components fabricated by printing and solution-based methods from hybrid materials: from transparent conductive electrodes to memory devices, transistors, light-emitting diodes, solar cells and sensor applications.

To enforce the synergy between the research groups, they decided to establish a new jointly used lab space for GenFab based in the new IRIS research building. The joint research place will open in summer/autumn 2020.

Read more: HySPRINT upgraded. Joint lab with Humboldt Universität