HySPRINT Photovoltaics Lab

Welcome!

Currently, the global photovoltaic market is dominated by solar cells based on crystalline silicon wafers. In research institutions and industrial development laboratories, the efficiency of such solar cells has been driven very close to the theoretical maximum.

The HySPRINT Photovoltaics Lab aims to develop new material combinations and processes for energy applications. The focus is on hybrid materials based on silicon and metal-organic perovskite crystals, which are used not only for energy conversion in photovoltaics but also for solar hydrogen production. Our work therefore focuses on addressing fundamental questions and new solar cell architectures, which can further optimize the efficiency and cost of solar energy conversion.

Furthermore, we would like to foster cooperation with industry, with a focus on photovoltaic and optoelectronic materials and devices at an early stage of technological development. In state of the art laboratories located in the Berlin-Adlershof Technology Park, we provide all relevant technological processes and characterization methods.

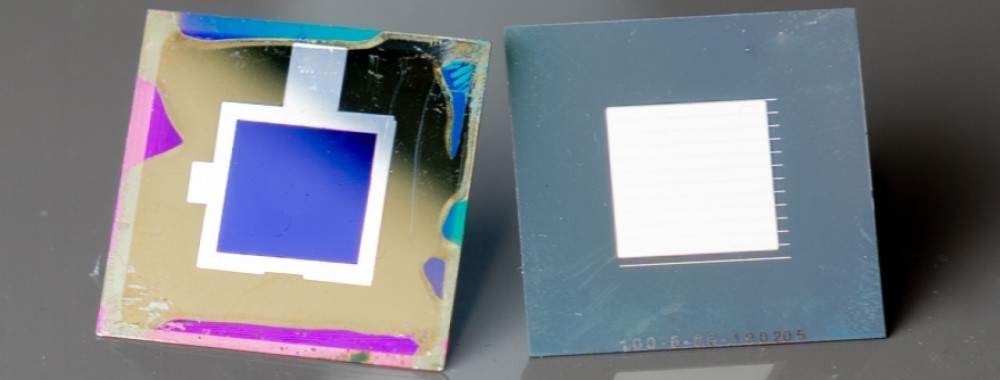

The world record perovskite silicon tandem solar cell fabricated at HySPRINT is based on two innovations: A nanotextured front side (left) and a back side with dielectric reflector (right). It has an area of about one square centimetre, a typical lab size. © Alexandros Cruz /HZB