PVcomB

Silicon Heterojunction Solar Cells

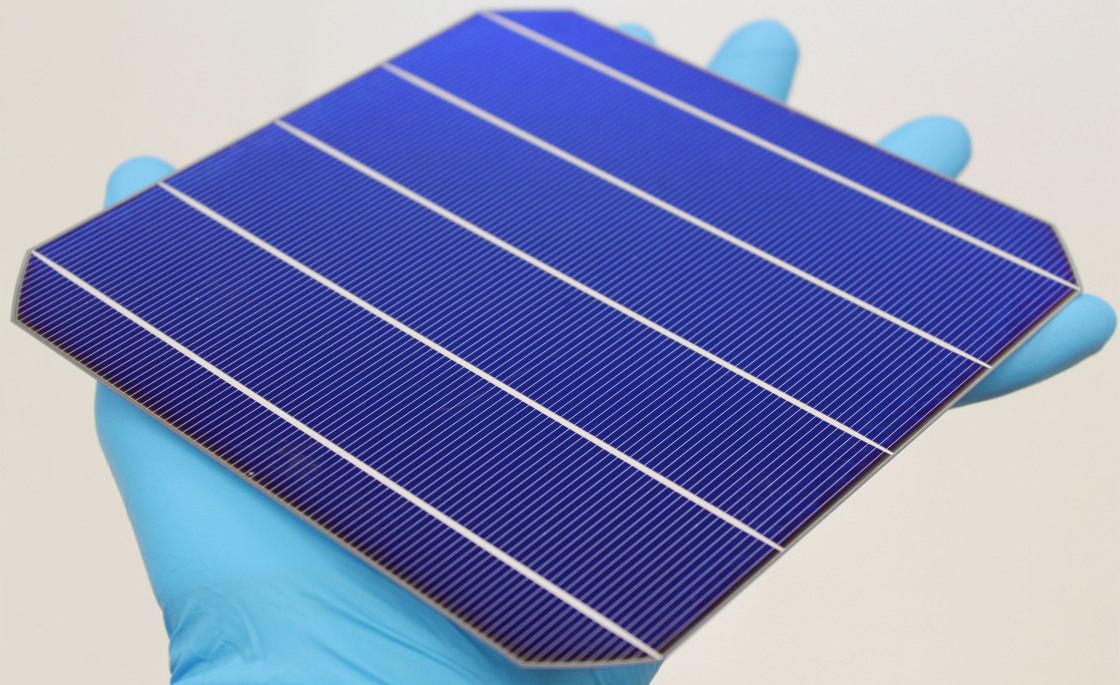

We provide a stable silicon heterojunction (SHJ) baseline for solar cell production of single junction silicon solar cells, as well as bottom cells for their application in perovskite/silicon tandem solar cells (see our teams for PVD Perovskite deposition and Si/Perovskite tandem baseline). SHJ technology provides solar cells with high efficiency and is especially suitable for upscaling a perovskite-silicon-tandem process.

At PVcomB, we operate a complete in-house process chain, starting from as-cut wafers and covering all essential fabrication steps to ensure high-quality and reproducible SHJ baseline processes. Our baseline SHJ solar cells currently reach a power conversion efficiency (PCE) above 24%.

Background Silicon Heterojunction Solar Cells

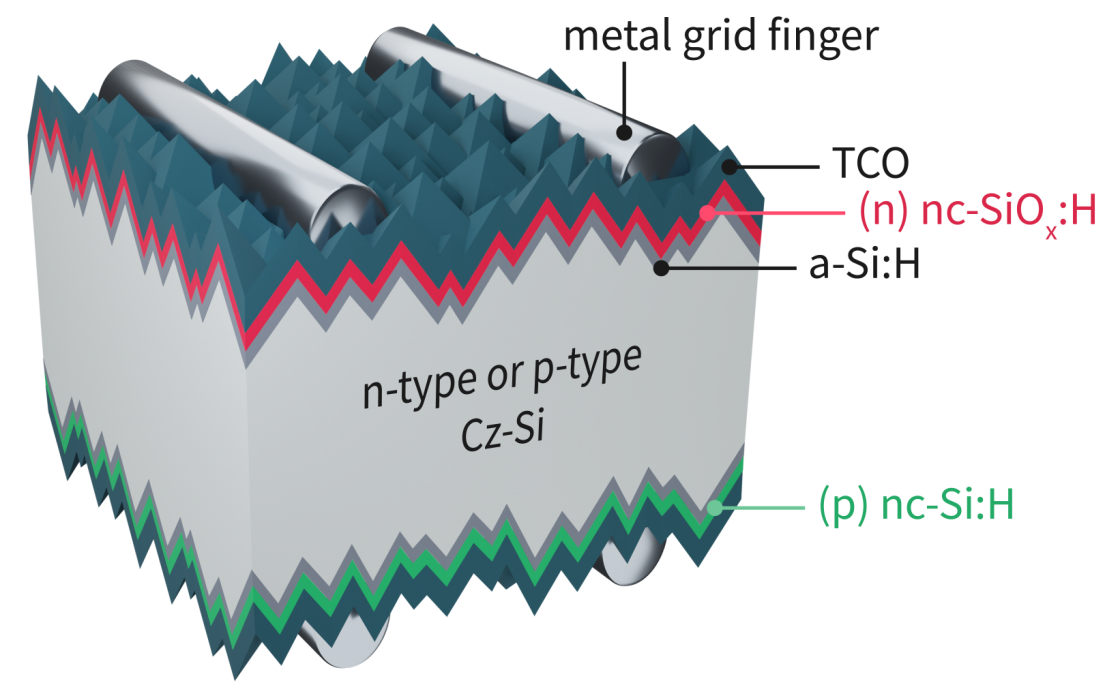

SHJ solar cells are fabricated from silicon wafers using passivated contacts for both polarities, based on i/n and i/p stacks of thin-film silicon alloys such as amorphous silicon (a-Si:H), nanocrystalline silicon (nc-Si:H), or silicon oxide (nc-SiOx:H). Thanks to the high quality of silicon wafers and excellent surface passivation, SHJ solar cells achieve very high conversion efficiencies, with open-circuit voltages exceeding 740 mV. The streamlined cell process sequence consists of just four major steps, all conducted at temperatures below 200°C, ensuring a cost-effective and scalable production process.

Bottom cells

SHJ solar cells serve as a bottom cell for integration into high-efficiency tandem architectures. In collaboration with multiple teams, we work on solution-processed and evaporated perovskite top cells, providing SHJ devices with tailored surface properties and morphologies to ensure compatibility with different perovskite deposition techniques.

For further details or collaboration opportunities, feel free to get in touch.

SHJ solar cell cross section (image by Laura Canil)