Öffnet in neuem Fenster

Opens in a new window

Öffnet externe Seite

Opens an external site

Öffnet externe Seite in neuem Fenster

Opens an external site in a new window

PVcomB

Materials Technology

The Photovoltaic to Fuels Technology Group develops and verifies technologically relevant processing methods for various electrochemical materials. Deposition processes, available for substrate sizes up to 10³ cm² for electro-catalysts and anti-corrosion coatings, are complemented by various electrochemical characterization tests to verify the functional performance of the materials.

Electrocatalysts

Deposition and analysis of earth abundant electrocatalysts on large areas for both hydrogen evolution reaction (HER) and oxygen evolution reaction (OER) via low-cost methods such as electrodeposition and evaporation.

Large area electrodeposition

Electrodeposited NiFeOx catalysts on 11 cm ×10 cm Nickel foam

Electrochemical characterisation

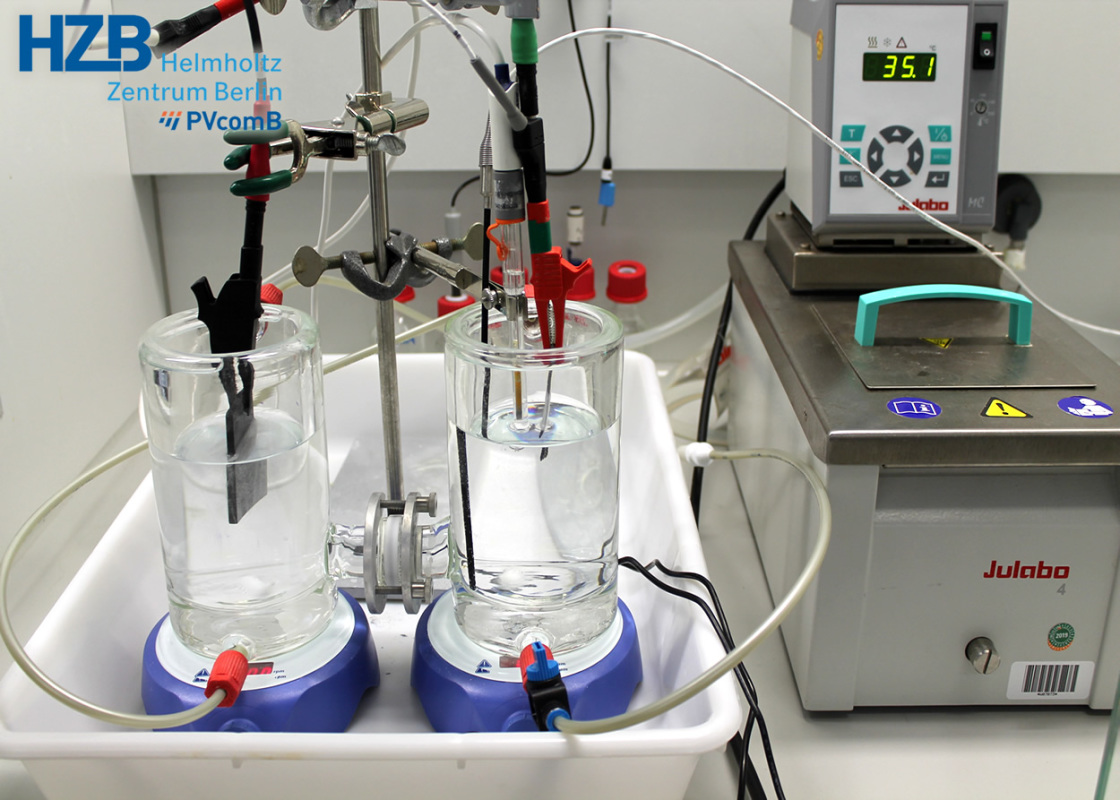

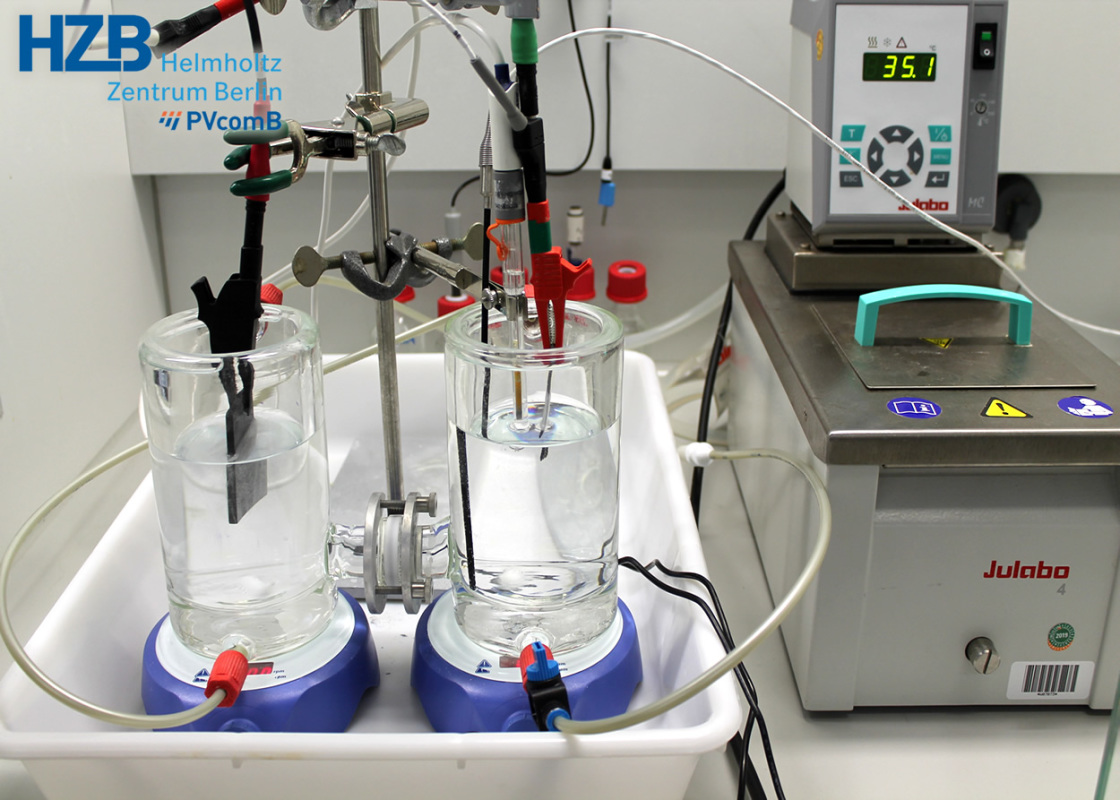

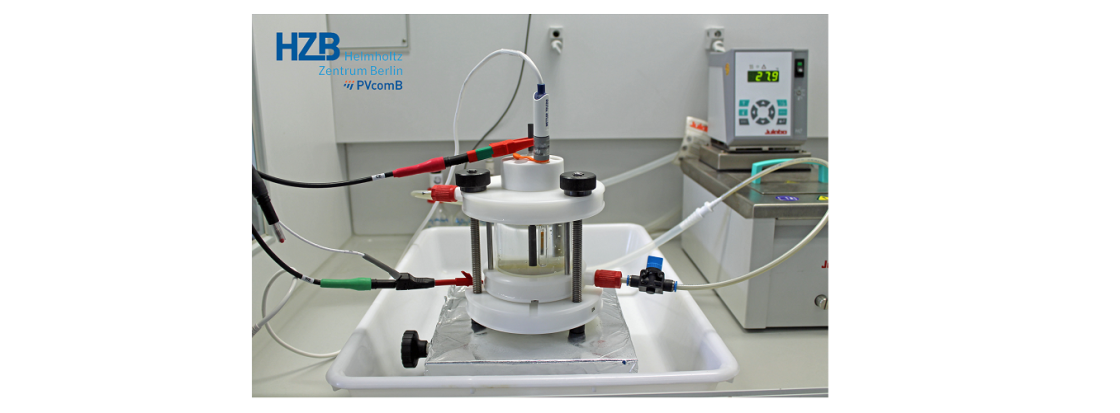

Thermostated H-cell allows investigation of the effect of temperature on the electrocatalyst properties

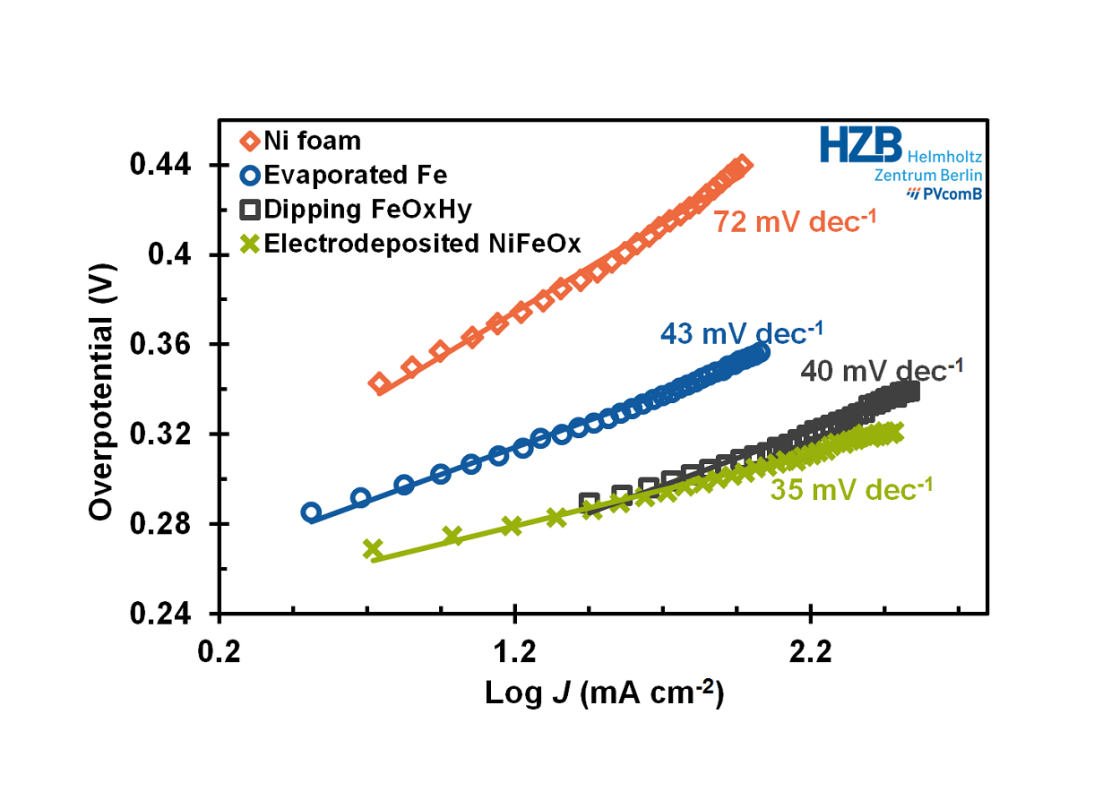

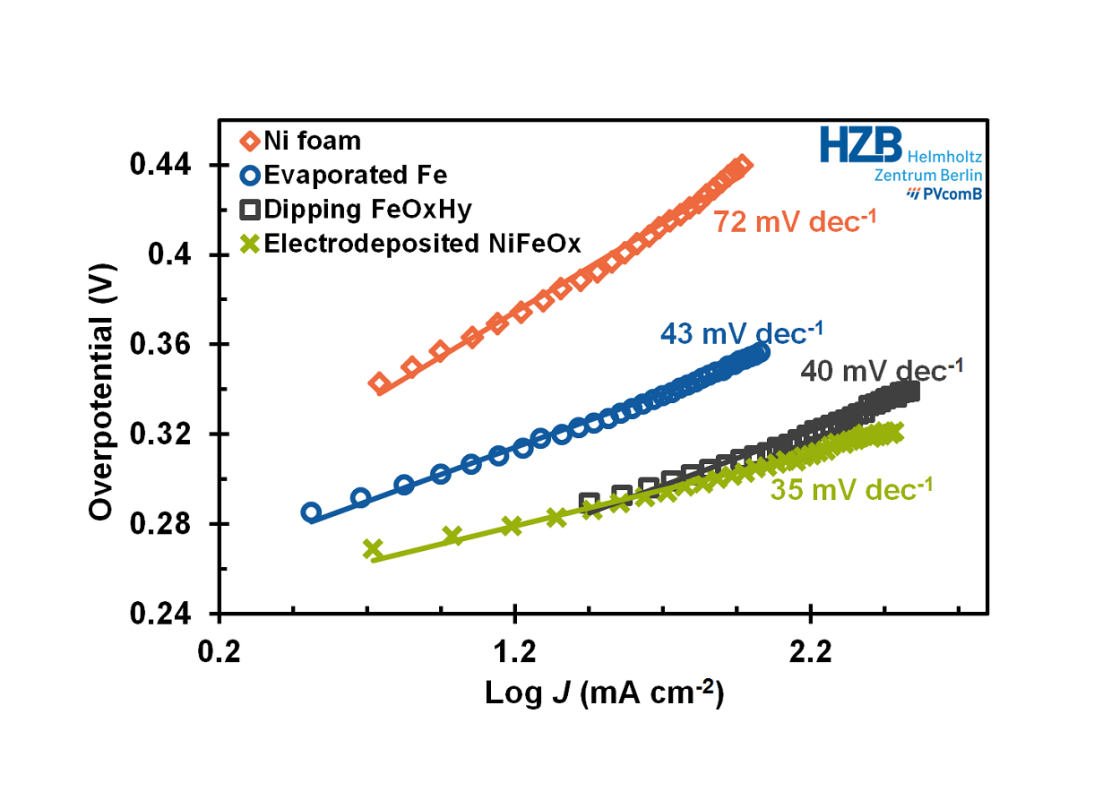

Tafel slopes for different electrocatalysts

Overpotentials from polarisation analysis of oxygen evolution reaction catalysts determined via using the following test conditions: 1.0 M KOH electrolyte, 25°C, 3-electrode configuration

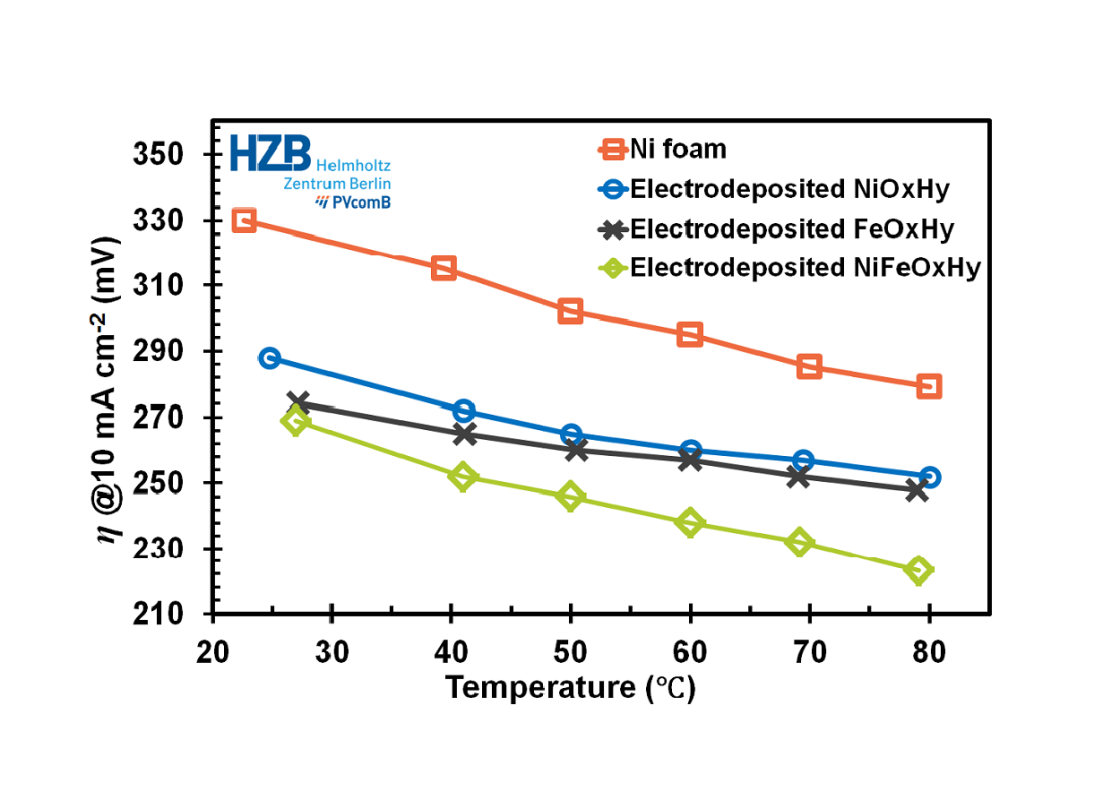

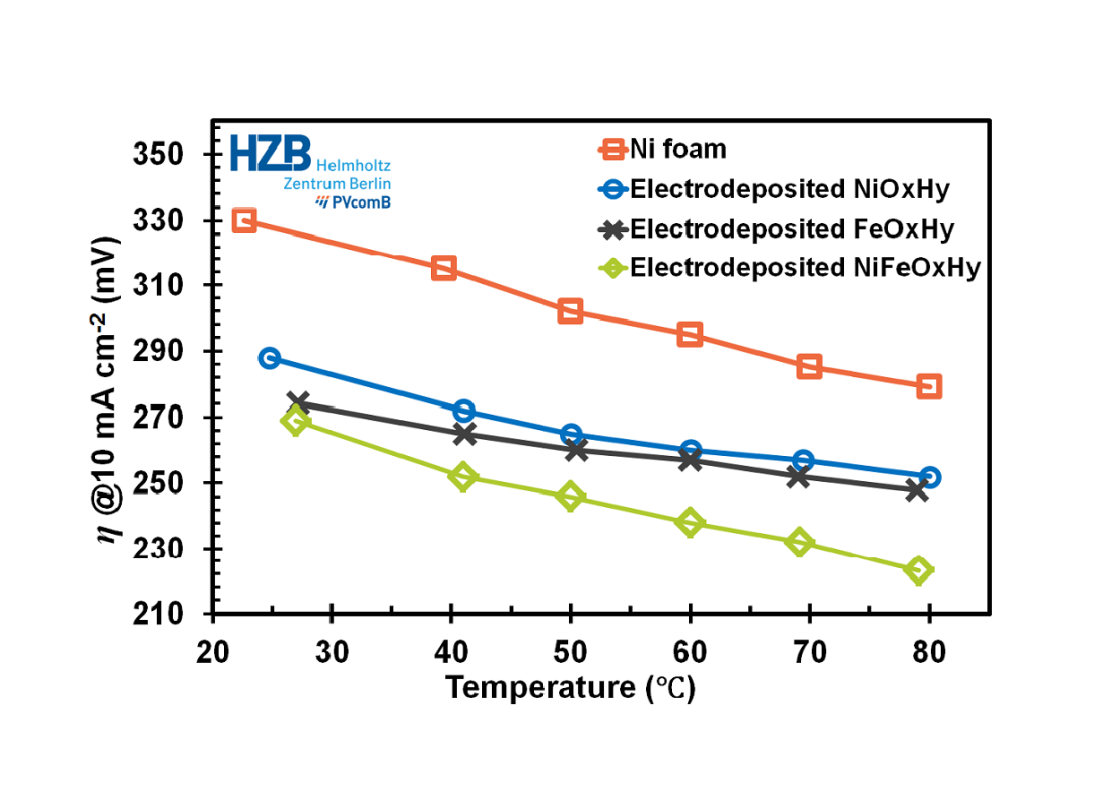

Temperature dependence of electrocatalyt overpotentials

Oxygen evolution reaction overpotentials at a current density of 10 mA/cm2 (geometric area) in 1.0 M KOH as a function of temperature in 3-electrode configuration

Anticorrosion coatings

- Development of anticorrosion coatings based on metal oxides such as TiOx, SnOx, etc.

- Incorporation of protective coatings onto photovoltaic modules and photoabsorbers cells at the interface with corrosive electrolyte.

- Corrosion testing of device components and anti-corrosion layers

Corrosion test on flat samples

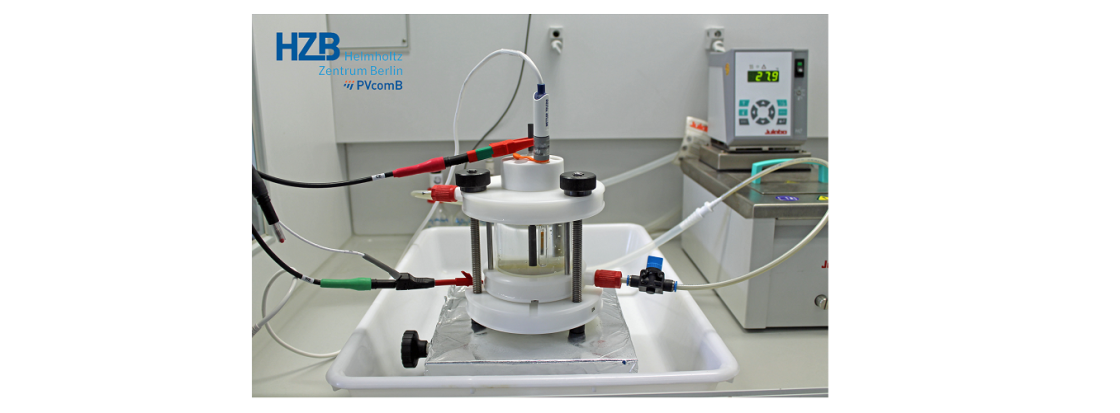

Thermostated corrosion cell allows investigation of the influence of different operation parameters such as the applied bias as well as the type, temperature, concentration and flow rate of the electrolyte, etc on corrosion protection

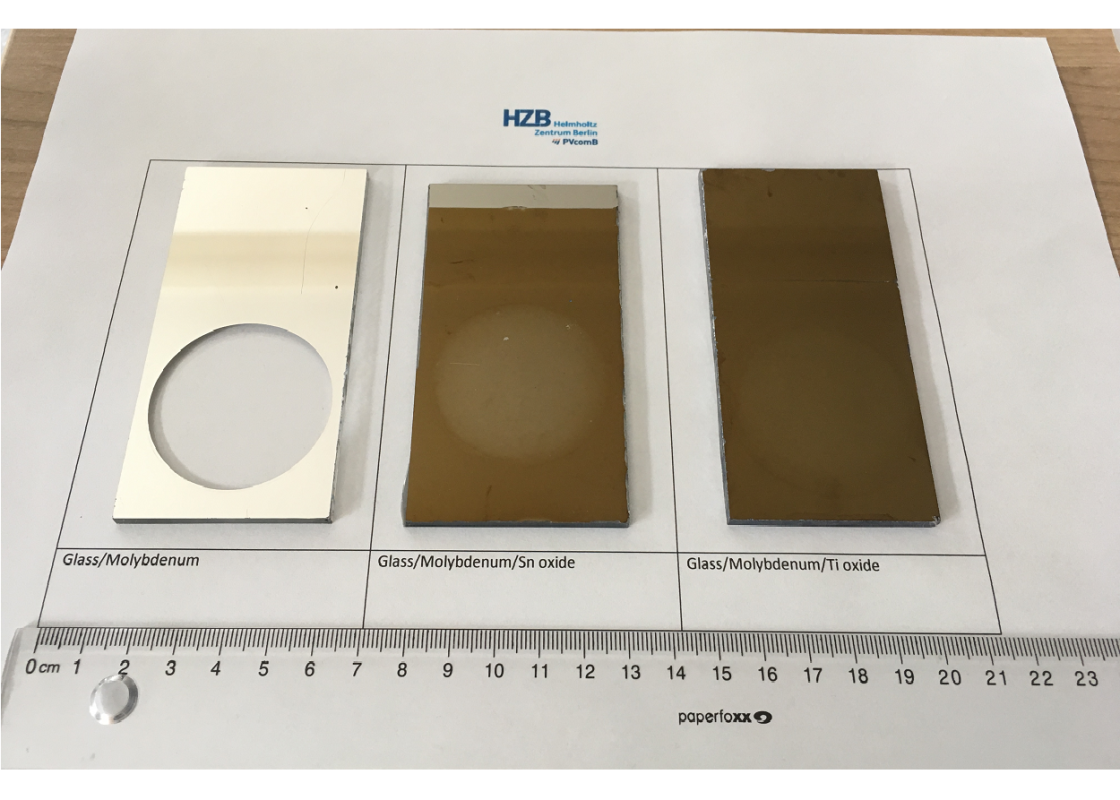

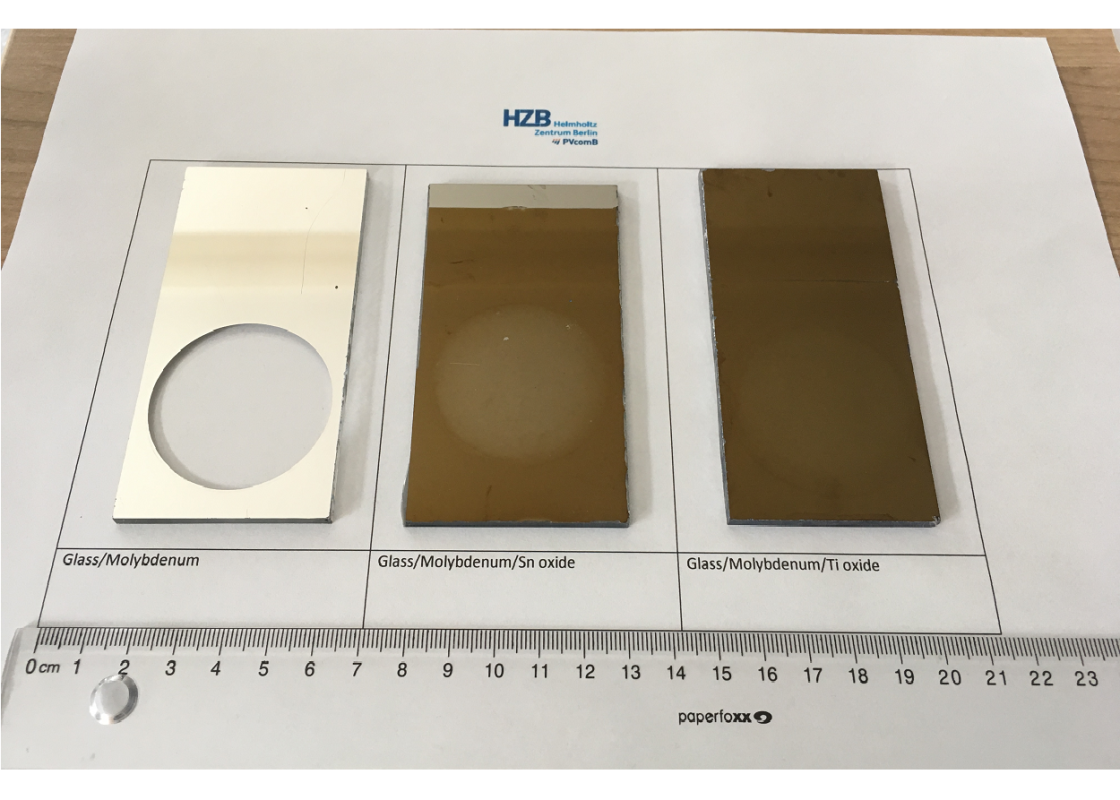

Anticorrosion protective layers

Photograph of (a) un- protected molybdenum, (b) SnOx – and (c) TiOx- protected molybdenum after exposure to 1.0 M KOH

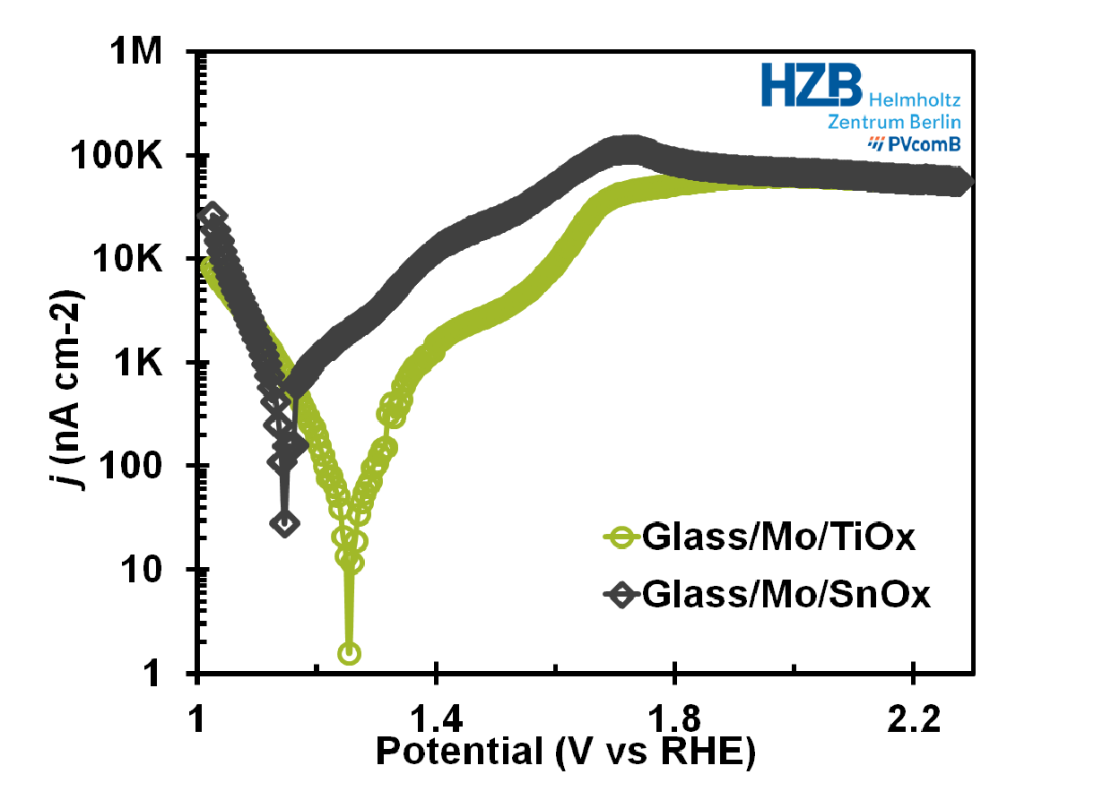

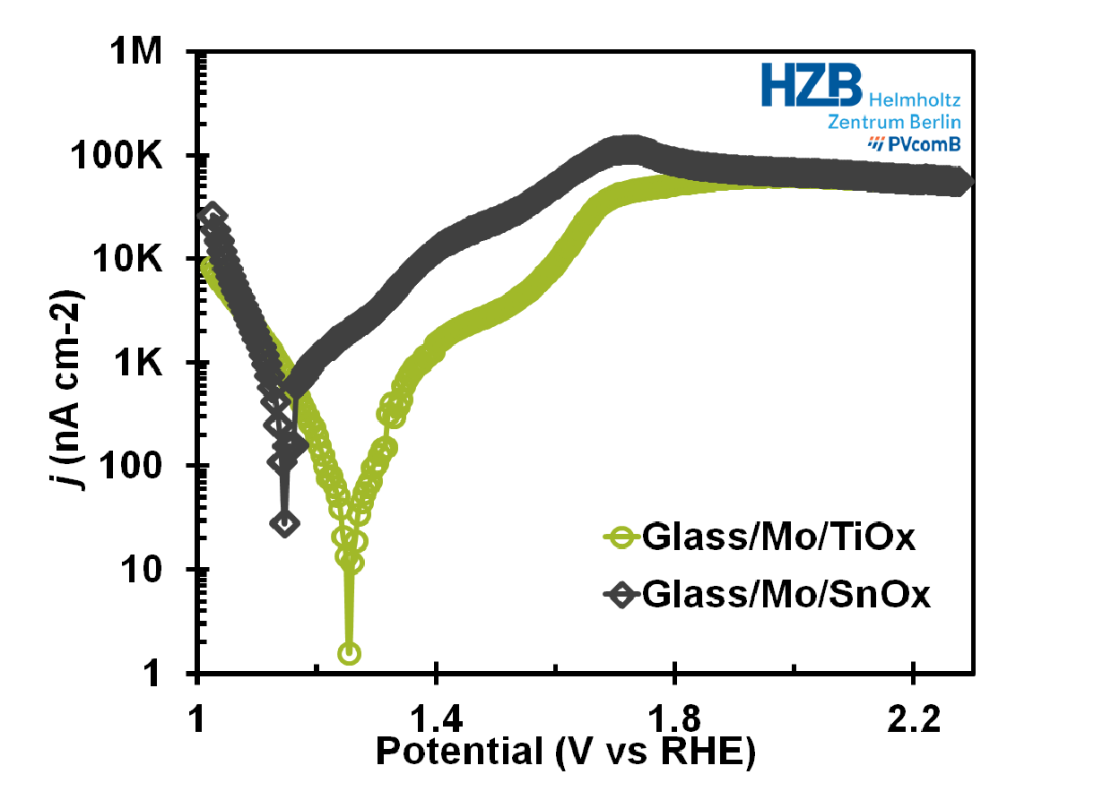

Potentiodynamic Polarization Test

Polarisation curves for Glass/Mo/TiOx and Glass/Mo/SnOx in 1.0 M KOH with applied potential varied from -250 mV to +1000mV vs Eocp, scan rate: 5 mV/s at 25°C