Imaging

Imaging techniques provide insights into the interior of materials.

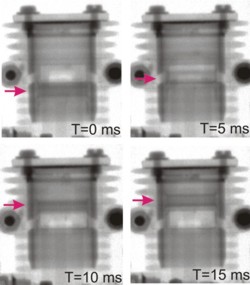

Radiography

Stroboscopic radiography of a model airplane engine at 1200 revolutions per minute. Four different phases for the position of the piston are shown.

Radiography of components

Radiography allows non-destructive insights into the interior of components and components. In particular, the combination of this technique with the unique properties of different types of radiation (neutrons, X-rays) opens up a wide field of industrial applications. The material-dependent attenuation of the radiation used in the objects to be examined is used to ‘illuminate’ the internal structure.

Tomography

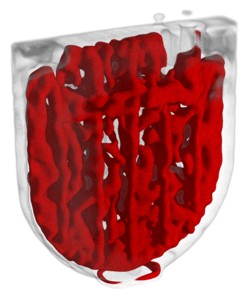

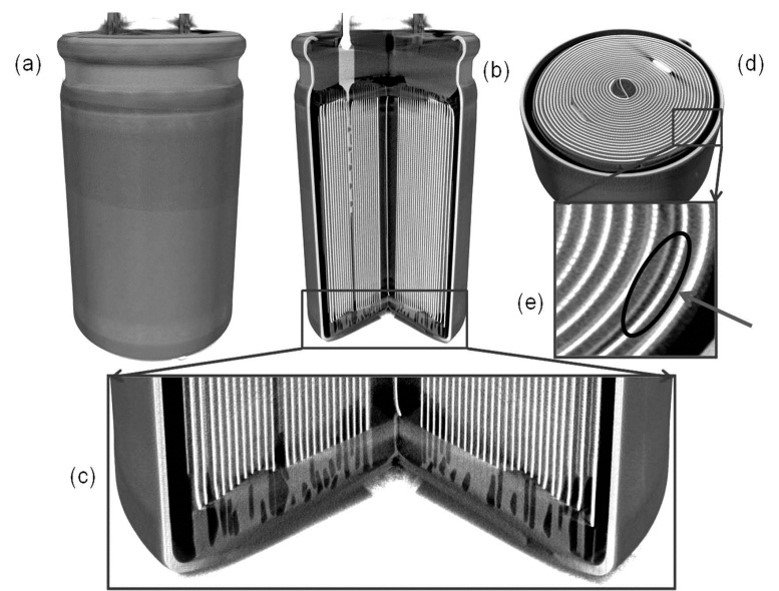

Tomography of batteries using neutrons and X-rays

A complete, three-dimensional image of the entire internal structure is obtained by radiographing the object to be examined from different directions and then combining these data into a three-dimensional data set (i.e. tomography). The result is a spatial image in the virtual space, which can be disassembled at any place at will, cut up or examined for structural or chemical changes. Again, X-rays and neutrons are used. Both types of radiation behave in a way complementary to each other, as they reflect different properties of the materials studied. Thus, with neutron radiation, material contrasts are visible that are not to be found with synchrotron radiation and vice versa.

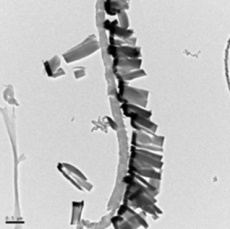

Transmission Electron Microscopy

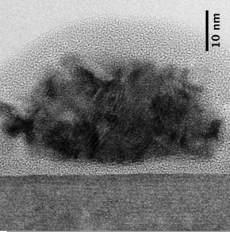

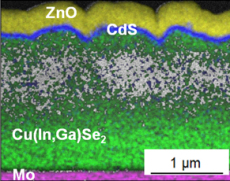

Structure analysise of solar cell systems using TEM

Transmission electron microscopy (TEM) enables a wide range of high-resolution inspection methods, including scanning electron microscopy (STEM), electron energy loss spectroscopy (EELS), energy-filtered transmission electron microscopy (EFTEM), and energy dispersive X-ray spectroscopy (EDX) and tomography.

Microscopic ultrastructure investigation of solar cells by means of high-resolution TEM methods for the determination of defects that are directly related to the photovoltaic efficiency of solar cells.