Residual stress analysis using neutron and X-ray diffraction

For the investigation of load, composite and residual stresses of materials and components, we at HZB use complementary methods for illuminating different penetration depths. By means of energy-dispersive X-ray diffraction, internal stress depth gradients from the surface are made visible in a depth of approximately 100 μm (for example for steels). These can also be resolved in multiple layers of coated components. By contrast, neutron diffraction can be used to analyze stresses in several millimeters (for aluminum even in several centimeters). This provides a broad spectrum for applications from various industrial sectors, for example:

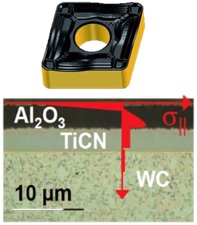

- Multilayer coating system on the surface of cutting tools

- Components for the automotive industry, as well as for aerospace

- electronic components

- Components from additive manufacturing