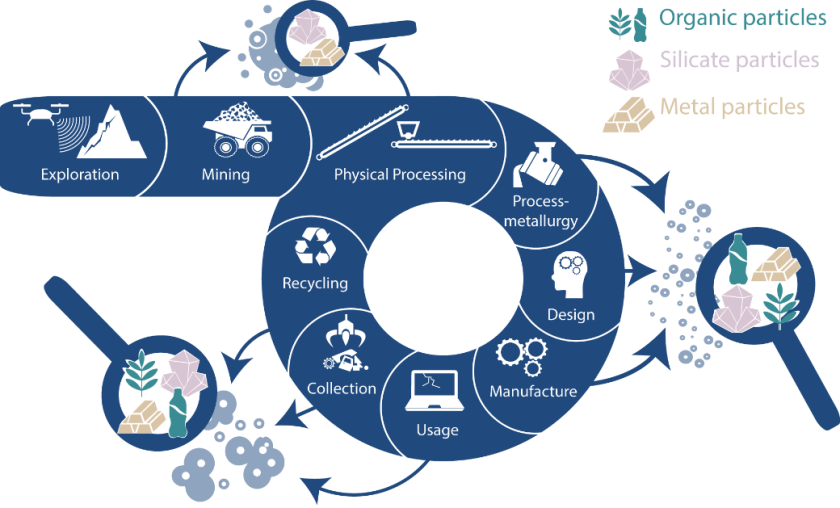

Fine particles back into the raw material cycle

Within three subprojects, organic, metallic and fines that could be recycled into cement are being investigated. © FINEST

Industrial processes always produce fine-grained residues. These rarely find their way back into the industrial value chain, but are usually disposed of and represent a potential environmental risk. The FINEST project records and investigates various of these fine-grained material flows with the aim of developing new concepts to keep them in the cycle and safely dispose of remaining residues.

FINEST was successful in the Helmholtz Association's sustainability competition and will now receive 5 million euros in funding.

The project is coordinated by the Helmholtz Institute Freiberg for Resource Technology (HIF) at the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) and involves teams at the Helmholtz-Zentrum Berlin (HZB), the Karlsruhe Institute of Technology (KIT), the Helmholtz Centre for Environmental Research (UFZ), the TU Bergakademie Freiberg (TUBAF) and the University of Greifswald.

The HZB is participating in FINEST in a project on the degradation of microplastics. "Together with the UFZ, we want to investigate how microplastic particles can be degraded, for example by bacterial enzymes that we improve on a structure basis. In addition, we also want to work with the HZDR to develop new detection methods for micro- and nanoplastics," says Dr. Gert Weber, who conducts research in the Macromolecular Crystallography Group at the HZB.

Starting in July 2022, the researchers from the six participating institutions will work in the five-year project on ultra-fine materials of anthropogenic origin such as microplastics, mineral additives (additives) or metals, for which there are currently hardly any recycling options. Innovative processes are to be used to increase the currently still very low recycling rates of these fine particulate materials and to deposit the remaining residues harmlessly in order to advance a sustainable circular economy.

Read the full text of the press release at the website of HZDR

HZDR/HZB

https://www.helmholtz-berlin.de/pubbin/news_seite?nid=23927;sprache=en

- Copy link

-

Sodium-ion batteries: New storage mechanism for cathode materials

Li-ion and Na-ion batteries operate through a process called intercalation, where ions are stored and exchanged between two chemically different electrodes. In contrast, co-intercalation, a process in which both ions and solvent molecules are stored simultaneously, has traditionally been considered undesirable due to its tendency to cause rapid battery failure. Against this traditional view, an international research team led by Philipp Adelhelm has now demonstrated that co-intercalation can be a reversible and fast process for cathode materials in Na-ion batteries. The approach of jointly storing ions and solvents in cathode materials provides a new handle for the designing batteries with high efficiency and fast charging capabilities. The results are published in Nature Materials.

-

10 million euros in funding for UNITE – Startup Factory Berlin-Brandenburg

UNITE – Startup Factory Berlin-Brandenburg has been recognised by the Federal Ministry for Economic Affairs and Energy as one of ten nationwide flagship projects for science-based start-ups. UNITE is to be established as a central transfer platform for technology-driven spin-offs from science and industry in the capital region. The Helmholtz Centre Berlin will also benefit from this.

-

Helmholtz Doctoral Award for Hanna Trzesniowski

During her doctoral studies at the Helmholtz Centre Berlin, Hanna Trzesniowski conducted research on nickel-based electrocatalysts for water splitting. Her work contributes to a deeper understanding of alkaline water electrolysis and paves the way for the development of more efficient and stable catalysts. On 8 July 2025, she received the Helmholtz Doctoral Prize, which honours the best and most original doctoral theses in the Helmholtz Association.