Department Optics and Beamlines

Multilayer-coated diffraction gratings for high transmission tender and soft X-ray energy range monochromators

A multilayer coating applied to a conventional diffraction grating can significantly enhance its diffraction efficiency for a selected diffraction order. This approach is particularly beneficial for high line density gratings, where the efficiency with a single-layer coating typically reaches only a few percent, whereas a multilayer coating can improve it by up to an order of magnitude. Additionally, substantial efficiency gains can be achieved for gratings operating in the tender X-ray energy range or those optimized for higher diffraction orders.

Among multilayer-coated gratings (MLG), blazed profile gratings (MLBG) hold the greatest potential for achieving the highest possible efficiency. However, laminar profile gratings (MLLG) also demonstrate significant improvements.

The key points for high transmission multilayer coted grating are fine optimization of multilayer and grating profile parameters to supposed operating angular condition and wavelength, mitigation of grating profile instability over the whole active aperture, ML interface sharpness, compromise in number of used ML periods and the grating profile smoothness.

The key factors for achieving high transmission in multilayer-coated gratings include:

- Precise optimization of multilayer and grating profile parameters to match the intended operating angles, wavelength and resolving power.

- Finding the right balance between the number of multilayer periods and overall grating performance and instrument angular conditions, grating acceptance.

- Ensuring grating profile smoothness by ML coating to maintain optimal diffraction efficiency.

- Considering of ML d-spacing value and interface sharpness to reduce expected losses to improve total efficiency.

- Minimizing grating profile instability across the entire active aperture or its compensation with ML parameters.

In our developments on multilayer-coated blazed gratings (MLBG), we have experimentally achieved efficiencies of up to 60% [1,2] in the tender X-ray energy range. In comparison, a single-layer-coated grating under similar operating conditions would typically exhibit only a few percent efficiency.

This high efficiency was achieved through a systematic approach that combined analytical and numerical simulations of MLBG performance [3] with experimental validation on carefully selected test structures. These test structures were fabricated in close collaboration with our in-house Precision Gratings department and external partners, including Tongji University, optiX fab GmbH, and AXO DRESDEN.

When employing a multilayer-coated grating (MLG) in a plane grating monochromator (PGM), the multilayer coating can also be applied to the monochromator’s plane mirror (PM). As a result, the total efficiency gain of a multilayer-coated optics PGM (ML-PGM) is a combined effect of enhancements on both the grating and the mirror, potentially leading to transmission increase of up to two orders of magnitude.

Our research demonstrates that, with precise optimization, an ML-PGM can cover a broad energy range using just a single grating. This also makes the ML-PGM the most optimal monochromator for the tender X-ray energy range, offering a unique combination of high throughput, stability, and resolving power.

Following several successful prototypes, the first fully functional multilayer-coated blazed grating (MLBG) was designed and installed in the c-PGM at the U41-TXM beamline at BESSY II [4].

In addition to our advancements in multilayer-coated blazed gratings (MLBGs), we have also made significant progress in the development of multilayer-coated high line density laminar gratings.

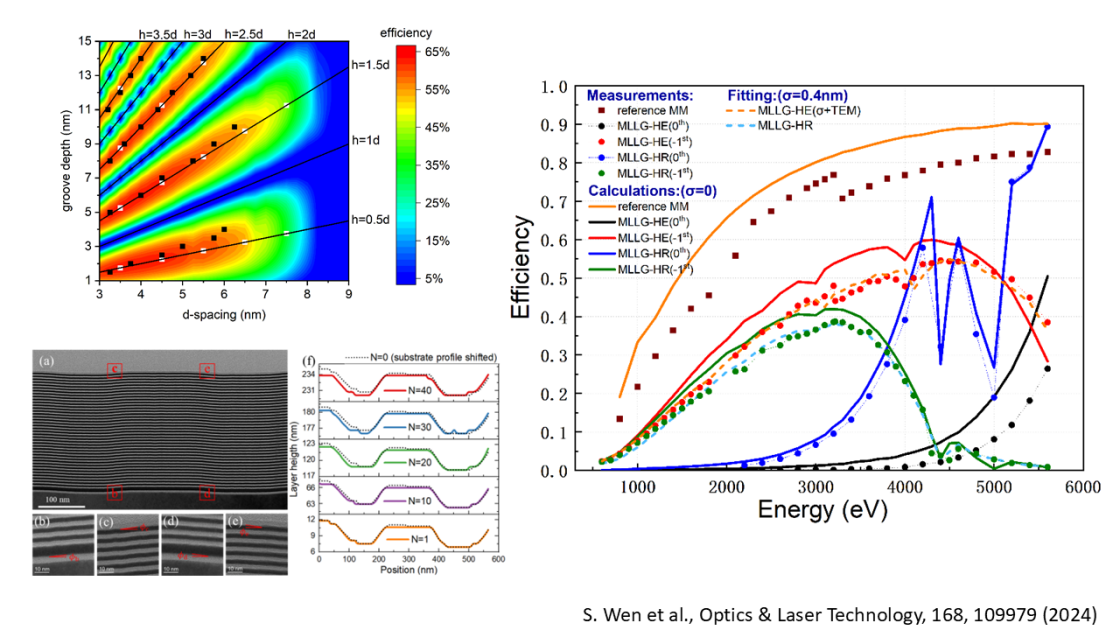

In our recent work, we demonstrated two possible optimization approaches—one for high resolution and another for high transmission. By applying these optimizations, we achieved an efficiency of 55% on a 3000 l/mm grating, marking a major step forward in enhancing the performance of laminar gratings.

The results of our research have already been implemented in several beamlines at our facility, including:

- UE41-TXM @ BESSY

- Microfocus Beamline @ PTB

We continue to advance our work on the following projects, where multilayer-coated gratings (MLGs) will be further optimized to push performance limits—operating at higher diffraction orders, integrating variable-line-spacing (VLS) gratings, and incorporating variable d-spacing multilayer designs:

- ELISA

- EMIL

- SoTeXs

- High-performance spectrometers (laboratory & FEL based applications)

Our publications:

1. F. Senf et al., “Highly efficient blazed grating with multilayer coating for tender X-ray energies”,Optics Express 24(12), 13220 (2016)

2. A. Sokolov et al., “Optimized highly efficient multilayer-coated blazed gratings for the tender X-ray region“, Opt. Express 27(12), 16833-16846 (2019)

3. Q. Huang et al., “Theoretical analysis and optimization of highly efficient multilayer-coated blazed gratings with high fix-focus constant for the tender X-ray region”,Opt. Express 28, 821 (2020)

4. S. Werner et al., "Spectromicroscopy of Nanoscale Materials in the Tender X‐Ray Regime Enabled by a High Efficient Multilayer‐Based Grating Monochromator" Small Methods, Volume7, Issue1, 2201382 (2023)

5. S. Wen et al., “High efficiency multilayer coated laminar gratings with high line density for tender X-ray region” Optics & Laser Technology, 168, 109979 (2024)

6. Y. Zhuang et al., “High-order multilayer-coated blazed grating for a high-transmission and high-resolution tender X-ray monochromator/spectrometer” Photonics Research Vol. 13, Issue 2, pp. 340-350 (2025)

7.