Institute Science and Technology of Accelerating Systems

SuperSurfer

Superconducting and Sustainable RF for Efficient acceleratoRs: SuperSurfer

Superconducting accelerators play a pivotal role in scientific research, enabling advancements in particle physics, nuclear physics, materials science, and a number of other fields. As society increasingly emphasizes sustainability and energy efficiency, the importance of implementing these concepts in accelerator technologies is evident. Presently, superconducting radiofrequency (SRF) technology is the most efficient method for particle acceleration available. Yet even for SRF systems, cryogenics for needed for cooling to 2 K is inherently very inefficient and can require multi-MW electrical power, dependending on the accelerator application. Were one to realize operation at 4.5 K, the efficiency improves by roughly a factor of three.

To achieve the goal of 4.5 K operation, bulk niobium must be replaced by another material with considerably lower surface resistance at this temperature. The most promising approach is to coat the inner surface of copper cavities (rather than Nb cavities) with an Nb3Sn layer, with a higher critical temperature than niobium. High-thermal conductivity copper is an ideal substrate, since Nb3Sn has a very poor thermal conductivity. The SuperSurfer project aims at a thorough investigation of a new, simpler approach based on the “Bronze Route” to implement such layers on copper cavities. Importantly, the use of a copper substrate also benefits conduction cooling (as opposed to liquid-helium cooling) of the dissipated heat, an essential aspect for the future implementation of cryocoolers. SuperSurfer explores new methods of Nb3Sn production, using state-of-the-art materials characterization techniques and innovative RF characterization systems developed in previous BMBF calls.

Cu-based Nb3Sn QPR sample preparation via bronze route

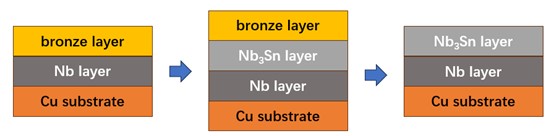

The bronze route is an achievable method to synthesize Nb3Sn thin films at 700℃ on Cu substrates for QPR sample preparation. This process involves a diffusion reaction between niobium and bronze alloy to form Nb3Sn. The copper will beis excluded from the Nb3Sn phase by itself and therefore, so it does not affect the superconductivity of the Nb3Sn film.

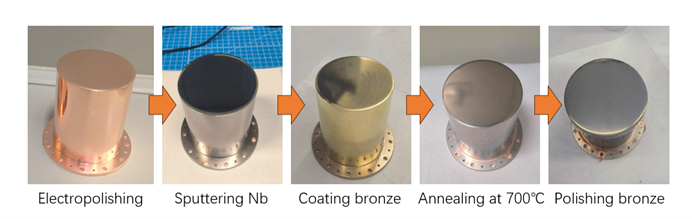

The process began with mechanical and electropolishing to achieve a smooth Cu surface, followed by the deposition of a Nb layer using HiPIMS. Then, a bronze precursor layer was electroplated onto the Nb-coated substrate, serving as the Sn source for the Nb3Sn formation. Next, 700°C heat treatment was performed to grow the superconducting Nb3Sn phase. Finally, the bronze on the surface was removed by chemical etching to obtain the final Cu-based Nb3Sn thin film.

The RF test of the first bronze QPR sample has been completed, and the surface resistance, critical temperature and critical magnetic field have been evaluated. Rs was measured to be about 76 nΩ at 2 K and 5 mT. The transition temperature and width of the Nb3Sn sample were found to be about 14 K and 4 K respectively. A severe Q-slope and RF heat limit were observed implying a poor coating quality for the first Nb3Sn/Cu QPR sample. Problems including low Sn content, surface defects and contamination, and copper exposure have been found, which will guide future process improvements.