Department Perovskite Tandem Solar Cells

Upscaling for Industrial Applications

Spin coating with antisolvent is still the leading method to achieve highest efficiencies and dominating the main laboratories’ daily research on perovskites. Yet, both the active area and application of various antisolvents limit the thin film formation homogeneity and the scalability potential. To overcome these limitations, we are developing scalable deposition methods such as slot die coating with N2 gas quenching and co-evaporation:

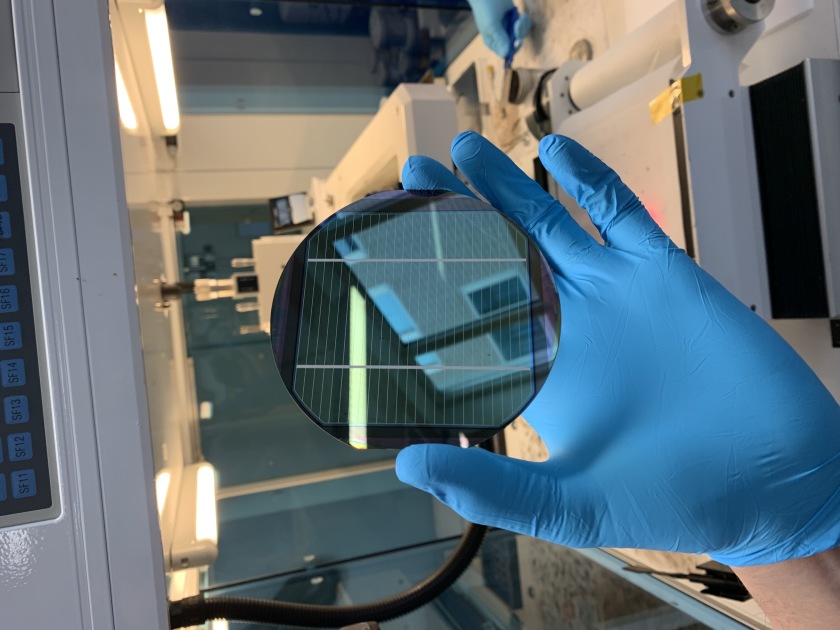

Wafer-size perovskite/silicon tandem solar cell. Picture: E. Köhnen / HZB

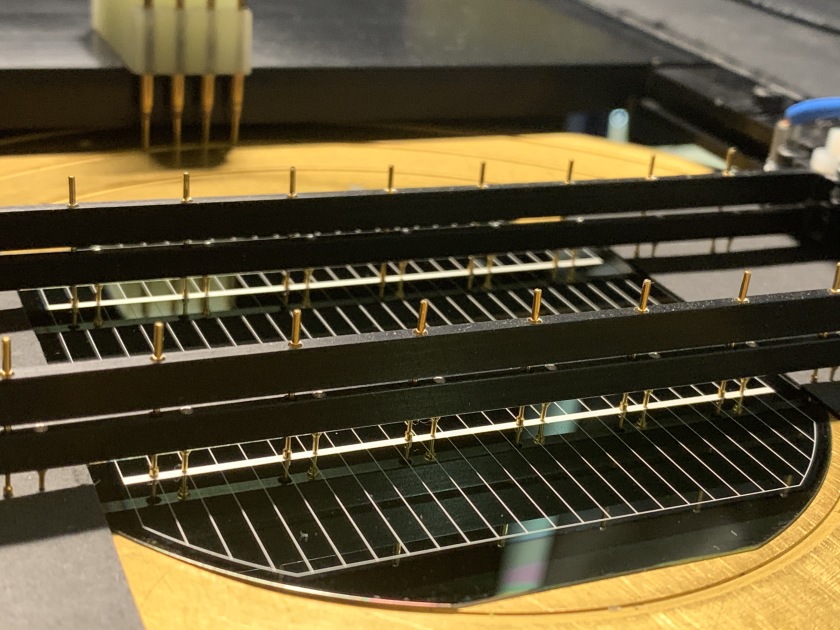

Characterization of wafer-size perovskite/silicon tandem solar cell. Picture: E. Köhnen / HZB

- In collaboration with the group Hybrid Materials Formation and Scaling, we develop new perovskite compositions which can be deposited with slot-die coating. Here, our focus is to develop perovskite absorbers with bandgaps applicable to tandems (>1.7 eV), achieving high photo- and thermal stability. In this context, a major challenge is to adjust deposition parameters for favorable film crystallization. The particular interest of our group is to develop suitable solvent systems enabling the growth of high-quality layers for wide-bandgap perovskite absorbers.

- Deposition of the active layers by vapor deposition rather than wet chemistry offers the advantage that the perovskite absorber can be deposited more homogeneously and conformally onto commercial, large-area, textured Si (or rough CIGS) solar cells. In previous studies, we investigated the growth of co-evaporated perovskite layers on pyramidally textured substrates [1] and the influence of substrate conditions during the evaporation process [2]. Here, we achieved a power conversion efficiency of 20.6% when using self-assembled monolayers (SAM, see also Development of New Contact Materials) as hole-transport layer (HTL) and optimizing the substrate temperature.

- To close the gap between research and (pilot) production, a vacuum deposition line (KOALA) for organic and inorganic functional and absorber layers for perovskite solar cells is to be set up at HZB in addition to the existing reference lines for silicon heterojunction and CIGS solar cells. In collaboration with the Silicon Heterojunction Solar Cells Group of Bernd Stannowski, these will form a pilot plant for the development of large-area (industrial-scale) tandem solar cells (pero/Si and pero/CIGS).

Key Publications:

- Gil-Escrig L., Roß M., Sutter J., Al-Ashouri A., Becker C., Albrecht S., Fully Vacuum-Processed Perovskite Solar Cells on Pyramidal Microtextures, Sol. RRL, 2021, 5, 2000553

doi:10.1002/solr.202000553 - Roß, M.; Gil-Escrig, L.; Al-Ashouri, A.; Tockhorn, P.; Jost, M.; Rech, B.; Albrecht, S.: Co-Evaporated p-i-n Perovskite Solar Cells beyond 20% Efficiency: Impact of Substrate Temperature and Hole-Transport Layer. ACS Applied Materials & Interfaces 12 (2020), p. 39261-39272

doi:10.1021/acsami.0c10898